MOQ stands for minimum order quantity and refers to the minimum number of products you can order from a supplier. Sometimes, it’s indicated in terms of money spent on purchases.

MOQs differ among manufacturers. Some, especially larger establishments, demand a large MOQ, while smaller operations offer a lower minimum, sometimes even just one unit.

Differentiating factors for MOQs include industry, product type, and product class.

An MOQ is important for an eCommerce business, especially during the start-up phase. It affects how much capital is tied up in procuring products from manufacturers — and the subsequent product storage. This can impact the company’s viability and ability to make a profit.

Let’s get to know more about MOQ and how to calculate it for your business so that you can use it to your advantage.

Reasons for a Minimum Order Quantity

Source: Pexels

A manufacturer imposes MOQ requirements on its customers to ensure the business is viable and profitable in the long term.

Manufacturing carries large fixed costs, like equipment maintenance and labor, alongside other variable costs, like raw materials. The manufacturer has to sell a certain number of products to cover these costs and be profitable.

If the manufacturer sells a quantity lower than their MOQ, the unit cost of the products will be unsustainably high, forcing the supplier out of business.

The production capacity is another determinant of a manufacturer’s MOQ. For manufacturers with large production facilities, it’s economically smart to set up MOQs that will cover their production expenses.

For online businesses, a minimum order quantity requirement is a different beast altogether.

What MOQs Mean for eCommerce Ventures

There are advantages and disadvantages for eCommerce stores when it comes to MOQs from suppliers.

The unit cost of products purchased under the MOQ requirements is the lowest price possible. The high number of products purchased makes this possible, enabling your eCommerce store to sell these products at a sustainable profit.

However, these lower costs come at a price — as the bulk purchase requires a large capital outlay for a minimum number of products, as specified in the MOQ terms.

There’s also the need to store these products.

Inventory costs make up a large part of an eCommerce venture’s running costs, comprising 20-25% of a product’s expenses.

There’s a risk that retail demand could be slow for these products, making for higher storage expenses. This can stifle the growth and development of the business as the majority of the cash flow is tied up in inventory.

For those starting out in eCommerce, it’s challenging to meet the MOQs of some suppliers, especially the larger ones. Calculating your own MOQ to know what quantity your business can profitably manage to purchase is one way to deal with this challenge.

Calculating Your Ideal MOQ

Source: Pexels

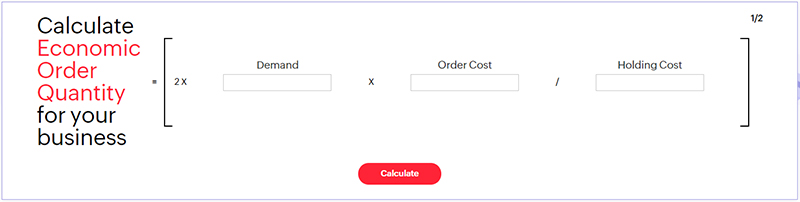

Rather than deciding on an arbitrary amount for your MOQ, there are empirical factors you can use to calculate the ideal figure. This order is also known as an EOQ (Economic Order Quantity) for eCommerce businesses.

The right MOQ should keep your ordering and storage expenses at a minimum and enable you to make a profit when purchasing from your suppliers. It should also be sustainable for the manufacturer to produce your order profitably.

Here are some factors to consider when determining your MOQ.

Demand Forecasting

You need to be able to foresee future demand for your products through demand forecasting.

This is done by looking at factors like demand growth, competing brands, and seasonality for each product type you sell. You should be able to gauge the average demand for each item.

Your demand forecasting abilities will help you recognize how much inventory you should have at a particular time. This will enable you to set an MOQ that is adequate for your needs and budget.

Ordering Costs

Ordering costs refer to the expenses used to buy your products from your suppliers. This includes transportation expenses.

To get the ordering unit costs per product, simply divide the overall ordering expenses by the product quantity. Based on the break-even point, you know how many products you have to sell to recover your total costs.

Storage Costs

Warehousing costs differ between products, depending on their nature. These costs have to be factored in when calculating your MOQ.

Here is a formula that combines these factors and helps you arrive at a useful MOQ:

Source: Zoho.com

Using the formula to arrive at an MOQ for each individual product type involves the following:

- Multiply the forecasted demand by the ordering costs.

- Multiply the result by 2.

- Divide the answer from step 2 by the storage cost.

- Finally, calculate the square root of the solution from step 3 to get your MOQ.

This MOQ formula will give you the optimal number of goods that you can order to achieve minimal storage and ordering costs. Use this figure to find a preferred supplier who will meet your ideal MOQ.

You can get more information about MOQ and other issues about moving your online business forward by joining eCommerce Fuel.

It’s a community of 7-figure+ eCommerce store owners whose practical experiences, along with the available resources, can help you navigate the eCommerce business terrain.

Getting the Best MOQs Possible

There are situations where you might not be able to get a supplier that offers your preferred MOQ. Here are some actions you can take to get a favorable deal.

Negotiation

You can negotiate with a supplier to give you a more favorable MOQ. It might be challenging getting manufacturers to accede to your terms, as their MOQ enables them to produce items profitably. But there will be one or two suppliers willing to accommodate your request.

Pre-Orders

You can get customers to prepay for your products. One way to do this is by having a crowdfunding campaign to attract customers. You can raise funds this way to meet the MOQ of your preferred manufacturer.

Parts Replacement

You can negotiate with a manufacturer to replace parts of the product you want with more affordable ones made with cheaper materials. This should help bring down the price to produce them, and by extension, the MOQ.

But you have to be careful that you don’t compromise too much in this regard. It can adversely lower the final product quality, which can in turn affect your business viability.

Fostering Positive Relationships

Building a friendly relationship with your supplier can be of benefit to you in the long term. You’ll be able to negotiate more favorable terms, especially on MOQs. A solid business performance on your part can further enhance this relationship.

Staggered Delivery

You can save on inventory costs while fulfilling a supplier’s MOQ by getting the products delivered at different times.

The information here should help you navigate MOQs, help your business grow, and become profitable.

Photo by Pexels