If your eCommerce business uses a warehouse for storage and distribution of goods, optimizing the warehouse is essential. By implementing the right technology, design, and processes, businesses can improve the efficiency and effectiveness of their warehouse operations, resulting in cost savings, improved customer satisfaction, and increased competitiveness.

The eCommerceFuel Forum has more than 300 threads about building, managing, and optimizing warehouses. We’ve distilled some of the best actionable advice to help you build and optimize your warehouse.

Designing an Efficient Warehouse

Warehouse Layout Tools

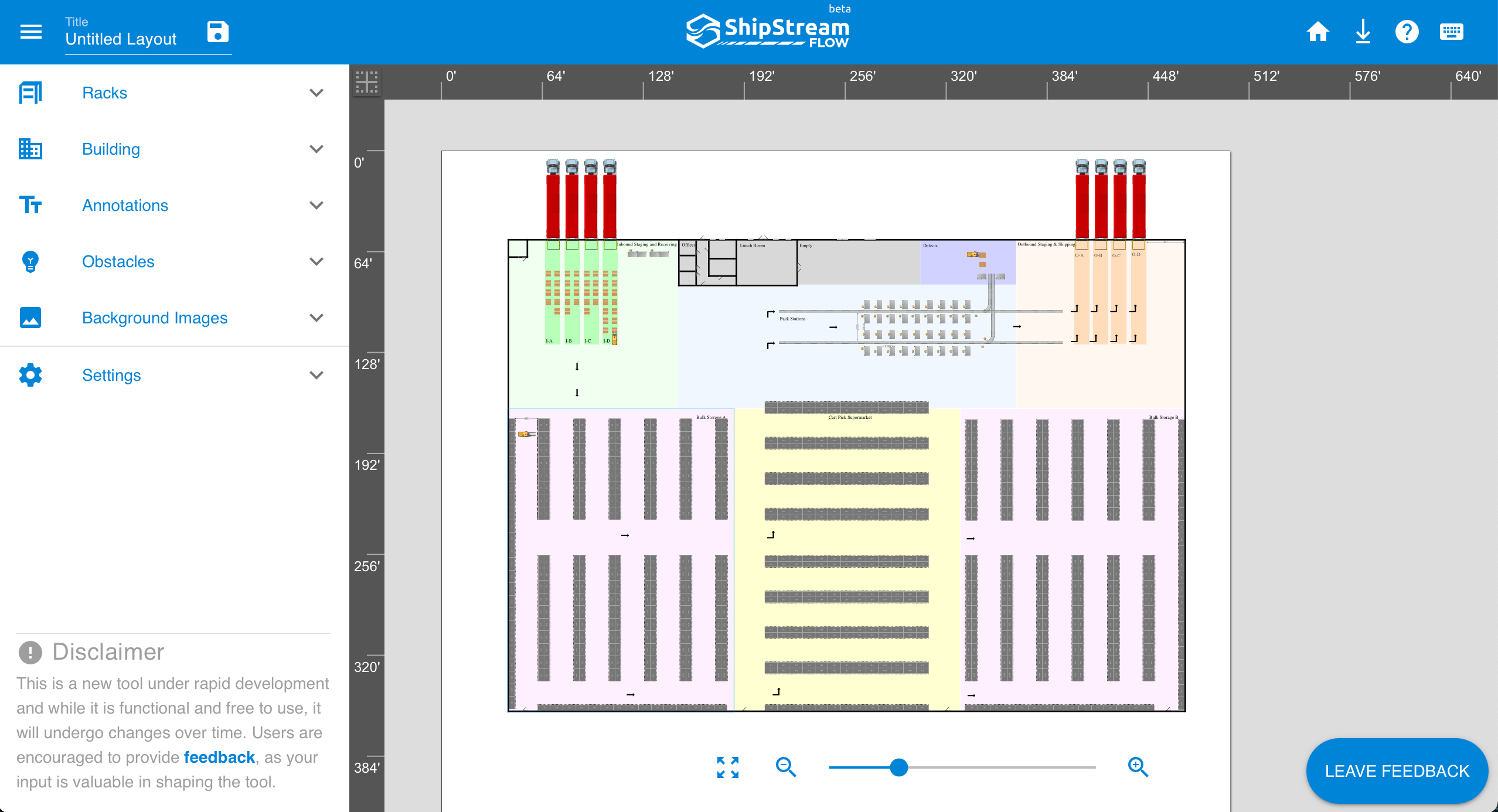

When designing the layout of your space, the eCommerceFuel community recommends modeling your needs and constraints in advance – and the easiest way to do so is with computer aided design (CAD).

AutoCAD is the gold standard and will allow for the greatest level of detail, but the learning curve can be steep for beginners. If you only need basic functionality, ShipStream provides a free tool called Flow specifically designed to help design your warehouse layout, and SmartDraw’s browser-based design tool features an approachable interface without compromising core features.

Another possibility, if you’re starting with a blank canvas, is to visit the site with a few rolls of tape and start marking out your rack locations on the ground. After marking everything with tape, members recommend transferring those measurements to a digital design to avoid mistakes in the execution of your plan.

Improve Warehouse Efficiency with Layout Analysis

The best way to improve productivity is to observe your warehouse in action.

Watch your employees, or even work a few shifts – when and why do they leave their stations? Are there items that they frequently must walk away for? How can you bring these items closer and minimize those wasted walks?

One forum member provides an excellent guide for improving warehouse efficiency via layout analysis. To analyze your layout install some cameras, then you or your warehouse manager spends an entire day watching the cameras and recording how many times your shippers leave the shipping area. You can record where they went, what they needed, and how many steps they took. Then at the end of the day take your results and create a heat map.

“My goal is for our shippers to do their pick list in the morning and literally never leave the shipping area the rest of the day. In fact we have a whiteboard right by the door to leave that says “What do you need?” We then take this list and optimize.

“A Water Spigot is a section of your shipping area that is only stocked with items that are needed all of the time. The hottest part of your heat map (the items they were always walking to get) take those items and put in the Water Spigot area in the shipping area. It should be close and easy for your shippers. Literally, 5 steps away and they have it. You will kick yourself as you realize some of your most common things are on the other end of the warehouse.”

Optimizing the layout of a warehouse is a never-ending task so don’t try to create the “perfect” layout. Instead, if you can make a couple of improvements this week do that immediately and see what happens. Then make a few more changes next week and so on.

Improving Warehouse Storage

If you think you’ve run out of room, chances are you haven’t. In many cases, the best way to go is up – take advantage of any vertical space you have, and use the floor savings to fit more stations, racks, or equipment.

If you keep any inventory, you need a shelving/rack system. The number and configuration of these racks is determined by:

- Product – What are the dimensions of your SKUs? Are your products assembled on-site, or do they arrive ready to ship?

- Process – Is inventory palletized and, if so, in what dimensions? How much will each pallet weight? How will your employees access these items? Will they need specialized equipment?

- Space – How many aisles can you fit in your warehouse space? How many do you need? How tall are the ceilings? With high enough ceilings, some members have found success with a Very Narrow Aisle (VNA) layout, which utilitizes taller storage units and specialized equipment for maximum productivity in a given space.

One of our members provides some additional considerations for selecting pallet racks:

Add wiggle room to your standard size pallet. Say your standard pallet is 40″ wide (fork side) x 42″ long. Someone may propose a 120″ beam which at first glance sounds ok, 40*3 = 120. But that won’t work unless you hire forklift gods because you need a little wiggle room. So now you go from 3 slots to 2 slots all because the rack isn’t 124″ instead of 120″.

Dense aisles increase equipment costs. Your aisle size affects the forklift you will select. You could double or triple your warehouse slot capacity by going from 13 feet (which fits the typical sit down lift) to 60 inches (VNA). But that requires a $50k forklift instead of a $8k forklift. Does the extra density pay for the more expensive lift?

Heavy pallets require study infrastructure. How heavy are your products? We have pallets that are 3,000 pounds and pallets that are 500 pounds. The heavier the load the larger beams (3, 4 or 6 inch) you’ll need to use in your warehouse. A larger beam is of course more expensive and takes up more vertical height.

After answering these questions and determining your specification requirements, use your chosen design tool to prototype the rack layout.

The community recommends the following sources for purchasing pallet racks:

- Craigslist – Can be hit or miss, depending on your local market

- Bidspotter.com – Online auctions, larger lots are often bundled and logistics of removing from seller’s warehouse can be difficult

- WarehouseRack.com and Material Handling Exchange – Large online resellers of new and used racking systems

As your aisles start to grow and fill, it’s important to have a precise method of location identification. A member shared this Location Number guide from Warehouse Coach that explains an alphanumeric location labeling system that can easily be integrated into your existing processes and quickly improve warehouse efficiency

Stations

The design of your packing and shipping stations will depend on your SKUs and process, but the community has a few tips to help streamline your warehouse operations:

- Keep the work area completely free of tools, equipment, trash, etc, and use magnets or a pegboard to keep tools nearby without cluttering the workspace.

- Integrate cameras into the station to help with process control, quality assurance, and customer disputes

- Make sure your work areas are adequately climate controlled – employees that are too hot/too cold will be less efficient

- Build a scale into the packing station

- Consider HDPE (a type of plastic) for your tabletops – it’s extremely durable, easy to maintain, and perfect for sliding packages around

ECF members regularly post photos and video demos of their custom packing stations. If you’re an eCommerce merchant consider applying.

Warehouse Operations

Warehouse Management Software

To maximize warehouse efficiency, reduce reduce mistakes, and streamline operations, your business needs the right software. Some of the ECF community’s suggestions for inventory and warehouse management include:

ShipHero Warehouse Management System

Founded by an ECF member, this digital solution includes order tracking, inventory management functions, mobile barcode scanning, rate comparisons, and automated reporting

Inventory-Planner.com

Supplement your inventory management with automated forecasting and purchasing

ShippingEasy

Cheap, lightweight solution with barcode scanner integration

Linnworks and Extensiv (formerly Skubana)

Popular community recommendations for integrated inventory /order management

Enterprise Resource Planning (ERP) Software

Enterprise resource planning (ERP) software is another type of warehouse management system that act as a connective tissue between disparate silos of information and processes. An ECF member explains:

“An ERP is accounting software first. It helps you track every incoming and outgoing dollar. The benefit is that everything within your business can be tied together in a financial perspective.

ERP systems track everything so you can’t do anything arbitrarily. If you do your numbers are off. ?There becomes a transaction or journal entry for LITERALLY EVERYTHING.”

In general, businesses with lower volume or fewer individual SKUs are less likely to need ERP integration, whereas those with larger and more complex operations be able to justify the large investment of both time and capital to get set up.

Understand Your Core Process: Pick & Pack

“Pick and Pack” is the central process of order fulfillment:

- An order is received

- The SKUs in that order are located and pulled from storage, and assembled into a complete order (Pick)

- The assembled items are placed into their shipping containers with any necessary void filler and sealed/labeled (Pack)

Large operations tend to separate their warehouse personnel into Pickers and Packers, but in smaller operations these may be combined into a single role.

In either case, the most-recommended system upgrade for pick/pack is a barcode scanning system. Many warehouse management systems natively integrate with barcode systems, and members almost universally find that they reduce both mistakes and fulfillment times. The gold standard of barcode systems is the international GS1 organization, which issues and manages the UPC codes printed on nearly every retail item for sale in the US.

Other process tips from ECF members include:

- Film everything

- Prevent packers from talking to each other

- Implement at least one quality control check – no order should leave the warehouse without being checked by someone other than the packer

- Document your processes with a standard operating procedure (SOP). In addition to providing a singular “source of truth” for training employees, creating the document itself will force you to define every part of your system

- Track everything, both with hard data in the form of KPIs and with cameras

Key Performance Indicators (KPIs) for Warehouse Efficiency

One of our members shared some warehouse efficiency tips from a high-level discussion on key performance indicators (KPIs):

“One consistent theme was a desire to move from lagging indicators to leading indicators. Many KPIs are “rear view window” and may not have predictive value. One presenter used historical KPI values and a spreadsheet to predict and manage growth rate.

The range of tools used to gather and present metrics were vast. Some of the tools mentioned were Fathom, LivePlan, and BeProfit.

More specifically, there were two broad categories of KPIs: operational and marketing. Marketing were sales, advertising, and conversion oriented. Operational included fulfilment, customer service, and inventory KPIs.”

Some other data points that members recommend tracking in your warehouse:

Order Processing Costs

In cost per package, recommended benchmarks change based on the size and quantity of items in each package.

One ECF member was able to ship ~30,000, small, low-quantity packages at an all-in cost of about $1.40.

Fulfillment Speed, Order Accuracy, & Inventory Accuracy

Speed is another important metric for warehouse managers, but be sure to track order and inventory accuracy in tandem or risk employees prioritizing speed at the cost of mistakes.

Using a unique incentive program, one member of the community was able to ship a “completely customized product at a rate 62% YoY at 100% per day with a 12pm cut off” during his peak season.

Inventory Levels

One member, whose business generates over $25 million per year, recommends measuring Gross Margin Return on Investment, Turn and Earn, and Direct Product Profit. He also shares his company’s document detailing the processes behind each of these metrics in the forums.

Staffing a Warehouse

Roles

One member recommends defining roles in your warehouse operations by structuring based on positions, not people:

- We wrote out all of our responsibilities we had in our company.

- I created an Org Chart based upon positions.

- “OK we need an Ops person, we need a Warehouse Manager, we need 3 shippers, we need…”.

- This was difficult to do but I forced myself to not think about PEOPLE but the actual POSITION.

- This requires you to be analytical and not emotional.

- Then in each of those positions we listed key skills and key metrics

- Then I re-interviewed my entire team and had them apply for each position.

- We legit had interviews and they showed up dressed up nice and applied for certain positions we thought they would be good at.

- We used personality tests so we knew if it was a good fit.

- There were lots of phycological benefits to doing this as well as it was clear we were changing how we do things.

- During that review period we had a scorecard for each position and role and then we rated each person on the skills needed and how we thought they would do on each of the key metrics.

- We moved people around to the positions that were best suited for them and turned them loose. The next quarter was amazing and they thrived.

- By doing this the losers had no where to run. Everyone had key roles they needed to perform in. Within 6 months we went from 25 employees to 18 and our team thrived or surged again. It was crazy to me that when you remove the baggage employees how it causes everyone to be more productive and love coming to work that much more.

Interviewing

The more effectively you can screen potential warehouse workers in the early stage, the more time you save interviewing bad fits. An easy way to do this is to require a simple question in your job application. One member suggests the following:

“If interested, please respond by email with your resume or work history and complete this sentence:

“I am the perfect choice for this part-time position because …”Over half of our applicants didn’t answer the question and those are the people who I don’t want to work with because they don’t want to do one extra step or they are unable to follow instructions.”

Retention

Good employees are not only a lucky find, but a significant investment, and you want to make sure they stick around. An ECF member shares how warehouse managers can incentivize growth in their workers:

“I have found that small frequent pay increases for taking on more responsibility and learning more about the operations of the business has built a system that encourages guys to keep learning. Often when guys have hit the top of the warehouse position they ask “so what else can I take on” which is really cool.”

Most members also suggest some type of incentive pay – identify your desired outcome, then reverse engineer the proverbial carrot that rewards that outcome. This is also an opportunity to experiment and get creative. Instead of offering only a standard quarterly or yearly bonus, for example, one member promises his employees a daily cash bonus for meeting performance targets. By playing into the human tendency to value immediacy, he’s found that smaller, more frequent incentive pay has greater return in warehouse productivity than a larger bonus promised in the future. Another member adds:

“As far as incentives it’s crucial not to just base it on one thing, because then the employees will maximize that one thing. So if you are going to base it off of orders shipped per hour then you better have accuracy as some variable in there too”

Final Thoughts: Improving Warehouse Efficiency

If you run an eCommerce business and handle your own fulfillment, optimizing the warehouse is essential.

It all starts with the right warehouse design paired with the right software to maximize the warehouse efficiency. Once you have the warehouse setup it’s time to monitor processes, optimize stations, implement KPIs, and hire the right team.

When you have a smooth and efficient warehouse you’ll be able to lower your costs, improve customer satisfaction, and reduce headaches.

Learn More in the Forums

We publish the full guides in the eCommerceFuel Forum. The full version in our private member forum is packed with real-world benchmarks, photos and videos of warehouses and operational setups, and even more detailed strategy suggestions.

In addition to live and digital networking opportunities by other entrepreneurs around the world, ECF members gain access to proprietary process documents and video walkthroughs, supplier reviews and recommendations, and hard-won tips and tricks, all shared freely with fellow community members by accomplished store owners.

To join, potential new members must own an eCommerce store with $1 million or more in annual revenue, and the application can be found here: Apply to Join eCommerceFuel