The industrial automation landscape is evolving rapidly, driven by a fundamental shift in how software solutions are developed and deployed. In the past, many factories had in-house IT expertise to build and maintain their basic software stacks, the present reality is quite different. Small-scale factories often lack the IT know-how to manage their increasingly complex digital infrastructure, and they often rely on contractors to set up and maintain their systems. The current industrial transformation is creating a unique set of challenges and opportunities, particularly for industrial players seeking cost-effective and comprehensive solutions to managing their industrial IoT Software.

The evolving industrial landscape

In this blog, we will discuss the adoption of hardware-agnostic, open-source industrial IoT software as an alternative to proprietary, legacy and hardware-bound IT solutions.

Challenges of legacy industrial IT solutions

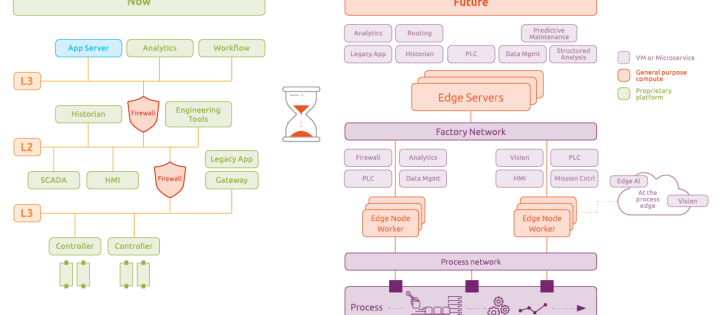

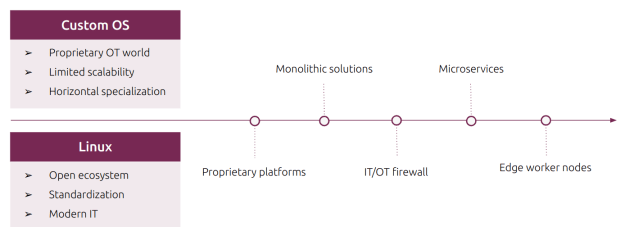

Among the most noteworthy market trends is the industry shift from fixed function and proprietary protocols to the adoption of open architectures with portable applications and multi-vendor interoperability. These legacy, closed-source platforms will be gradually transformed into or replaced by virtual machines and microservices over general-purpose open-source compute platforms, delivering the flexibility, interoperability and scalability that end customers desire.

Siloed solutions and ad-hoc efforts to tap into the fourth industrial revolution by funding one-time AI/ML and digitalisation projects in manufacturing fell short of their promises. Enterprises did not address the fundamental challenges behind the lagging security, updates and maintenance in industrial hardware, but only focused on applying the latest technologies. Legacy install bases and a lack of standardisation prevented industrial transformation from occurring. To fully reap the benefits of Industry 4.0, the industrial factory has to close the gaps between Operational Technology (OT) and IT. The convergence between the two domains calls for a transition from legacy stacks with closed standards and interfaces to modern IT solutions and the embrace of open-source software.

Furthermore, small-scale factories lack the financial resources to invest in expensive proprietary solutions, and they’re often hesitant to work with multiple suppliers due to the complexity it introduces. Partnering with one of the tech giants can be a significant commitment and lead to vendor lock-in, as these corporations may not offer the comprehensive, neutral solutions that smaller industrial players require. This is where the concept of an open-source “vertical stack” becomes essential.

The software-defined transition in industrial

An open-source vertical stack in Industrial IoT

Open-source software is rapidly becoming a driving force across the factory floor and in industrial IoT software.

As open-source software is typically more cost-effective than proprietary alternatives, small-scale factories can benefit from powerful, feature-rich solutions without breaking the bank. Open source also allows for greater customization, which allows Industrial players can tailor the software to their specific needs and requirements, delivering the flexibility to respond to changes in the business environment.

Another reason behind the increasing adoption of open-source industrial IoT software is the presence of ongoing community collaboration. Industrial solutions developed in the open are continually improved, and issues are resolved faster with the collective expertise of the open-source community. Similarly, open-source software is transparent, making it easier to audit for security vulnerabilities. This is crucial in the context of industrial automation where safety and security are paramount. Finally, open source ensures neutrality, reducing dependence on a single vendor. This aligns with the preference of industrial players to work with providers that offer comprehensive, neutral solutions.

For an approach to be comprehensive and to address the evolving needs of the industrial sector, it must be in the form of a vertical stack encompassing all the layers required for a complete industrial solution, from IT to OT. The goal is to offer a complete, open-source solution that aligns with market trends and addresses the challenges of the industrial IoT landscape.

Bridging the gap between IT and OT in industrial factories

The open-source Ubuntu Linux OS is the de-facto Linux standard in IT. Its use, however, is not limited to that world, as developers, innovators and the embedded community at large are also navigating the shift to the industrial edge with Ubuntu. Today, Ubuntu is the enabler behind the proliferation of connected, industrial devices. An Ubuntu-based vertical stack is a compelling solution for industrial IoT, as its approach is rooted in open-source software, providing a range of tools and technologies. It encompasses the entire spectrum of compute needs, from edge devices to cloud-based solutions, enabling a seamless transition from traditional industrial setups to modern, software-defined ecosystems.

Ubuntu’s technology suite includes secure, containerized packages that facilitate easy and efficient application deployment and maintenance. Similarly, adopting a lightweight Kubernetes cluster engine is ideal for edge computing and can bring scalability and flexibility to industrial solutions. Such a cluster and the Kubernetes workloads can also be effortlessly managed with open-source solutions running on Ubuntu. Ubuntu-based open-source technologies can also be used as industry-grade foundations to build human-machine interfaces (HMIs) by embedding graphic applications. Furthermore, industrial deployments can benefit from OCI container images that receive stable, secure and predictable security updates.

Software-defined vertical stack from the infrastructure to the applications

At the base of all these technologies, there must of course be a hardware-agnostic, embedded version of Ubuntu designed for Industry 4.0, offering a production-grade platform for integration, and secure, open-source development, and deployment. Embedded Ubuntu is an OS built from a new application packaging format portable across form factors, removing software boundaries between platforms. As an open-source, underlying base that can work across every layer of the automation pyramid, Ubuntu enables device manufacturers to capitalise on the wave of tightly embedded, industrial devices.

Open-source OS from the IT desktop to the industrial devices on the factory floor

Ubuntu Core, the embedded version of Ubuntu, is designed from the ground up to host industrial applications on-premise. With Ubuntu Core and its surrounding ecosystem, industrial pioneers can access a secure, containerised, and ready-to-go platform to jump-start their Industry 4.0 journey. Ubuntu Core bridges the gap between OT and IT by bringing the same level of security, long-term maintenance, OTA updates and interoperability across form factors to all the levels of the industrial factory. By removing fragmentation, Ubuntu provides the same consistent and secure user experience across the entire industrial compute spectrum.

Future of open-source Industrial IoT software

In the dynamic landscape of industrial automation, embracing open-source solutions is the path forward. An Ubuntu-based vertical stack approach, powered by open source, offers a cost-effective, customizable, and secure way for industrial factories to navigate the complexities of IT-OT convergence and software-defined devices. As the industry continues to evolve, open source is proving to be the key to addressing the unique challenges and opportunities in the world of industrial IoT. Ubuntu’s vertical stack provides the necessary foundation for this transformation, empowering industrial players to thrive in the era of open-source industrial IoT.