In the dynamic landscape of modern commerce, the warehouse industry stands at the forefront of innovation, adapting to the ever-evolving demands of global markets. With the rise of e-commerce, rapid delivery expectations, and the quest for operational efficiency, the convergence of Artificial Intelligence (AI) and automation has emerged as a game-changer. This article explores the profound impact of AI and automation on warehouse operations, unraveling the intricate tapestry of technological advancements that are reshaping the way goods are stored, managed, and dispatched.

The integration of AI and automation has ushered in a new era of warehouse management that transcends traditional paradigms. This article delves into the myriad ways in which AI-driven insights and automated processes are enhancing inventory management, optimizing order fulfillment, and revolutionizing the entire supply chain. From predictive maintenance that anticipates machinery needs to robotics that collaborate seamlessly with human counterparts, the warehouse industry is undergoing a transformation that promises not just efficiency gains but also a fundamental shift in how businesses deliver value to their customers.

As we navigate the landscapes of AI and automation in the warehouse industry, it becomes evident that this transformation extends beyond mere technological implementation. Change management, human-robot collaboration, security considerations, and the ethical implications of job displacement are all critical facets that demand careful examination. By exploring both the opportunities and challenges presented by this technological leap, this article aims to provide a comprehensive understanding of the multifaceted nature of this revolution.

Moreover, this article seeks to bridge the gap between academia and industry, fostering a dialogue that enriches both research and practical application. Through case studies, empirical analyses, and expert insights, we aim to offer a holistic view of AI and automation’s impact on warehouse operations. From startups to established enterprises, this article serves as a valuable resource for decision-makers, researchers, and technologists alike, empowering them to navigate the complexities of this transformative journey.

In the subsequent sections, we will delve into the diverse applications of AI and automation within warehouse operations. We will explore how these technologies enhance inventory management, streamline order fulfillment, optimize resource allocation, and drive unparalleled operational excellence. We will also critically examine the challenges that organizations face in adopting and integrating these technologies, seeking to offer strategic insights that pave the way for successful implementation.

In the pursuit of redefining the warehouse industry, this article embarks on an exploration that transcends the boundaries of traditional logistics. As AI and automation revolutionize the way goods move, the human ingenuity driving this evolution remains at the heart of the narrative. With this article as a guiding light, we embark on a journey into the future of warehouse operations, where innovation meets pragmatism and transformation meets tradition.

Robotic Process Automation (RPA)

Robotic Process Automation (RPA) is a technology that uses software robots or “bots” to automate and perform repetitive, rule-based tasks within digital systems. These bots mimic human interactions with user interfaces and software applications, carrying out tasks just as a human employee would, but at a significantly faster pace and without errors.

RPA is not about physical robots; instead, it’s about software automation that operates within digital environments and may or may not interact with physical Robots.

Specifically, Robotic Process Automation (RPA) proves advantageous in handling tasks necessitating information exchange among disparate applications, facilitating the automation of human-operated activities. Should a bot need to interact with a non-user interface accessible system, it can employ web services to retrieve or transmit data.

RPA holds significance in the integration of workflow applications and legacy enterprise systems lacking accessible backend APIs. It also serves as a beneficial independent tool for aiding business users in accomplishing their routine tasks.

Key Features of RPA

- Automation of Repetitive Tasks: RPA is designed to handle tasks that are routine, repetitive, and rule-based. These tasks can include data entry, copying and pasting information, data extraction, calculations, and more.

- User Interface Interaction: RPA bots interact with software applications and user interfaces just like human users. They can click buttons, fill out forms, navigate menus, and manipulate data within applications.

- Software Integration: RPA can integrate with a wide range of software applications, including legacy systems, without requiring extensive changes to existing infrastructure. This integration enables bots to perform tasks across various platforms.

- Scalability and Consistency: RPA bots can be easily scaled to handle larger workloads and multiple instances of a task. They maintain a high level of consistency in task execution, reducing errors caused by human variability.

- Rule-Based Logic: Bots follow predefined rules and logic to execute tasks. They can be programmed to make decisions based on specific conditions and inputs.

- Speed and Efficiency: RPA bots can work 24/7 without breaks, leading to increased speed and efficiency in task execution. They can complete tasks much faster than human counterparts.

- Data Handling: RPA bots can extract, process, and input data from various sources, enabling data migration, synchronization, and validation tasks.

- Audit Trail and Logging: RPA processes leave a detailed audit trail, which is useful for tracking actions, identifying errors, and maintaining compliance.

- Non-Invasive Implementation: Implementing RPA does not require major changes to existing systems. Bots can be developed and deployed relatively quickly.

- Minimal Training: RPA bots are trained through recording and playback of tasks, making training relatively straightforward and less time-consuming compared to training human employees

- Cost Efficiency: RPA can lead to cost savings by reducing labor costs associated with repetitive tasks and by minimizing errors that can be costly to rectify.

RPA is applied across various industries and sectors, from finance and healthcare to manufacturing and customer service. It can be a transformative technology for organizations seeking to improve operational efficiency, reduce errors, and allocate human resources to more strategic and creative tasks.

However, it’s important to note that RPA has limitations. It’s best suited for tasks with clear rules and defined inputs and outputs. Tasks that require complex decision-making, creativity, empathy, or understanding nuanced contexts are less suitable for automation using traditional RPA techniques.

Overall, RPA plays a significant role in the digital transformation journey of organizations by enhancing processes, optimizing efficiency, and contributing to better customer experiences.

Key Components in RPA

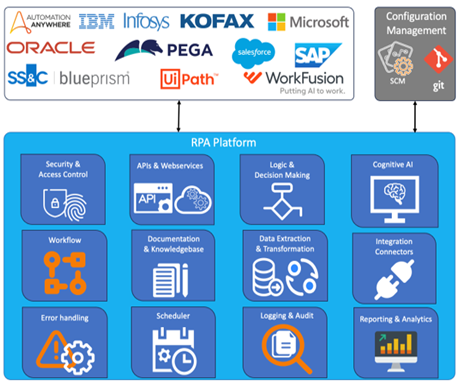

A Robotic Process Automation (RPA) bot consists of various components that work together to automate tasks and processes. These components in Fig. 1, ensure that the bot can interact with applications, manipulate data, make decisions, and perform the desired actions. Here are the key components of an RPA bot.

- User Interface Interaction Module: This module allows the bot to interact with the user interfaces of various applications. It can mimic human actions such as clicking buttons, filling out forms, and navigating menus.

- Data Extraction and Transformation: This component enables the bot to extract data from various sources, transform it as needed, and input it into other applications. It involves tasks like data entry, copy-pasting, and formatting.

- Logic and Decision-Making: The logic module contains the decision-making capabilities of the bot. It determines the flow of actions based on predefined rules, conditions, and inputs.

- Workflow Control: This component manages the sequence and flow of tasks that the bot performs. It ensures that actions are executed in the correct order and handles exceptions that may arise.

- Integration Connectors: These connectors allow the bot to interact with different systems, databases, and applications. They facilitate data exchange between the bot and external sources.

- Error Handling and Exception Management: The error handling module detects and manages errors that occur during bot operations. It can trigger corrective actions or provide notifications when an unexpected situation arises.

- Logging and Audit Trail: This component maintains a record of bot activities, including actions performed, data transformed, and decisions made. It’s crucial for tracking and analysis.

- Security and Access Control: Security mechanisms ensure that the bot operates within defined access rights and follows security protocols. This prevents unauthorized access to sensitive information.

- Schedulers and Triggers: These components allow bots to be triggered based on specific events, schedules, or triggers. This is useful for automating processes at specific times or in response to certain conditions.

- Reporting and Analytics: This module generates reports and provides insights into bot performance, task completion, and efficiency gains. It helps monitor the bot’s impact on operations.

- Cognitive and AI Integration: Some advanced bots incorporate cognitive capabilities, such as natural language processing or machine learning, to handle tasks that require understanding and interpreting human language or complex data.

- Integration with APIs and Web Services: This component enables the bot to connect with external applications and services using APIs (Application Programming Interfaces) and web services, facilitating data exchange and integration.

- Configuration Management: This module allows administrators to configure and customize bot behavior, rules, and parameters to adapt to changing requirements.

- Documentation and Knowledge Base: This component stores documentation, guidelines, and knowledge about the bot’s functionality, configuration, and usage.

RPA is ideally suited for dealing with large volumes of data, which involves the digitization of all sorts of applications and processes in all verticals. For example, in a warehouse if multiple robots work in tandem and generate huge volume of data, then this needs to be processed in real-time. In such a scenario, RPA requires low-latency computing, which can be achieved by edge data centers.

Edge data center requirements are much the same as those in a traditional data center, including robust computing, storage, and network resources, as well as sound physical and cyber security. But it all must be delivered in a much smaller package.

Edge Infrastructure refers to a technological framework designed to bring computing capabilities closer to industrial equipment and processes, enabling real-time data processing, analytics, and decision-making at the edge of the network rather than relying solely on centralized cloud computing. This approach is particularly valuable for manufacturing, energy, transportation, and agriculture industries, where latency, bandwidth, security, and autonomy are critical concerns.

Key components and concepts of industrial edge infrastructure include:

- Edge Devices: These are the sensors, actuators, controllers, and other hardware components that collect and transmit data from industrial equipment and processes. These devices can include IoT sensors, PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition) systems, cameras, and more.

- Edge Computing: Edge computing involves processing data locally on edge devices or gateways rather than sending all data to centralized cloud servers. This reduces latency and ensures real-time or near-real-time analysis and decision-making.

- Edge Gateways: These devices act as intermediaries between edge devices and the central IT infrastructure. They aggregate data, preprocess it, and transmit relevant information to the cloud or data center while performing local analytics as needed.

- Data Processing and Analytics: Edge infrastructure allows for local data processing and analytics, enabling organizations to gain insights and take actions in real time. This is particularly beneficial for applications where immediate responses are crucial.

- Connectivity: Edge infrastructure relies on various connectivity options, including wired (Ethernet, fieldbuses) and wireless (Wi-Fi, cellular, LoRa) communication protocols to facilitate data exchange between edge devices, gateways, and the central network.

- Security: Security measures are critical in industrial edge environments to protect sensitive data and prevent unauthorized access. This includes encryption, authentication, and monitoring at the edge level.

- Autonomy: Industrial edge infrastructure enables localized decision-making, reducing the dependency on cloud connectivity. This is especially important in scenarios where network interruptions can lead to operational disruptions.

- Scalability: Edge infrastructure should be designed for scalability to accommodate growing numbers of edge devices and evolving data processing requirements.

- Use Cases: Industrial edge infrastructure is applied to various use cases, such as predictive maintenance, quality control, real-time monitoring, asset tracking, and process optimization.

- Hybrid Approach: Many industrial setups employ a hybrid approach that combines edge computing with cloud computing. This enables organizations to strike a balance between local processing and analysis and, centralized data storage and long-term analytics.

Implementing industrial edge infrastructure involves selecting appropriate hardware, networking solutions, edge computing platforms, and software tools. It offers benefits like reduced latency, improved efficiency, enhanced security, and better compliance with regulatory requirements.

Keep in mind that advancements in technology and the industrial sector can lead to changes and developments in the concept of industrial edge infrastructure.

Challenges

Robotic Process Automation (RPA) offers significant benefits in terms of automating repetitive and rule-based tasks, improving efficiency, and reducing human error. However, there are several challenges that organizations may encounter when implementing RPA:

- Process Complexity and Suitability: Not all processes are suitable for RPA. Complex, non-standard, or highly variable processes can be challenging to automate effectively. Identifying the right processes for automation is crucial.

- Change Management: Introducing RPA often requires a shift in the way employees work. Resistance to change and concerns about job displacement can hinder successful implementation. Proper change management strategies are essential.

- Data Quality and Integration: RPA relies heavily on data input. Inaccurate or incomplete data can lead to errors and inefficiencies. Integrating RPA with different systems and ensuring data accuracy and consistency can be complex.

- Scalability and Maintenance: Scaling RPA from a few bots to an enterprise-wide deployment can be challenging. Maintenance of RPA bots, including updates, changes to processes, and handling exceptions, requires ongoing effort.

- Security and Compliance: RPA can access and manipulate sensitive data. Ensuring proper security measures, access controls, and compliance with data protection regulations is essential to avoid data breaches and legal issues.

- Bot Orchestrations: Coordinating the actions of multiple bots across various processes can be complex. Ensuring that bots work seamlessly together without causing conflicts or inefficiencies is a challenge.

- Process Changes and Updates: If the underlying processes change frequently, RPA bots may become outdated and require constant reprogramming. This can offset some of the efficiency gains.

- Cognitive Limitations: RPA is not adept at handling tasks that require complex decision-making, reasoning, or understanding context. Processes that involve subjective judgment or human interaction may still require human involvement.

- Cost Considerations: While RPA can lead to cost savings over time, initial implementation costs, including licensing, training, and infrastructure, can be significant.

- Vendor Lock-in: Organizations may become dependent on a specific RPA vendor’s technology and tools, making it challenging to switch vendors if needed.

- Performance Monitoring and Analytics: Monitoring the performance of RPA bots, identifying bottlenecks, measuring their impact on productivity, and generating meaningful analytics can be challenging.

- Regulatory and Legal Challenges: RPA deployment may need to adhere to specific industry regulations and legal frameworks, which can impact the design and operation of automated processes.

- Misalignment of Expectations: Unrealistic expectations regarding the capabilities and outcomes of RPA can lead to disappointment if the technology doesn’t meet those expectations.

- Lack of Skilled Resources: Finding and training employees with the necessary technical skills to develop, deploy, and maintain RPA bots can be difficult.

To successfully address these challenges, organizations should conduct thorough planning, involve relevant stakeholders, invest in training, and continuously evaluate the effectiveness of RPA implementation. It’s important to view RPA as a strategic initiative that requires ongoing attention rather than a one-time deployment.

Conclusion

In conclusion, the transformation of warehouse operations through the strategic implementation of AI and automation stands as a pivotal advancement in the modern supply chain landscape. This paper has explored the remarkable potential that arises from harnessing the power of these technologies to revolutionize the way warehouses operate.

Through real-world use cases and practical examples, it is evident that AI-driven insights and robotic process automation (RPA) have the capacity to reshape traditional warehouse processes. By optimizing tasks such as order processing, inventory management, quality control, and data validation, warehouses can achieve unprecedented levels of efficiency, accuracy, and responsiveness.

The integration of AI not only enables predictive analytics to minimize stockouts and reduce excess inventory but also empowers warehouses to proactively adapt to changing demands. Automation, on the other hand, ensures seamless execution of processes, reducing human error and accelerating throughput. This amalgamation leads to a leaner, more agile, and customer-centric distribution network.

However, the journey towards transforming warehouse operations is not devoid of challenges. Organizations must navigate issues related to data security, integration complexities, employee upskilling, and change management. Yet, the potential rewards—enhanced competitiveness, improved customer satisfaction, and cost savings—far outweigh these hurdles.

In essence, the convergence of AI and automation is ushering in a new era for warehouse operations. As technology continues to advance and innovation unfolds, warehouses are poised to evolve from traditional storehouses of goods into dynamic, intelligent hubs that drive efficient supply chain management. In this era of continuous evolution, it is imperative for organizations to embrace the synergy of AI and automation, adapting their strategies to remain at the forefront of the industry. By doing so, they position themselves to harness the full potential of these transformative technologies and reshape the future of warehouse operations.